Integrated Annual Report

Ontex at a glance

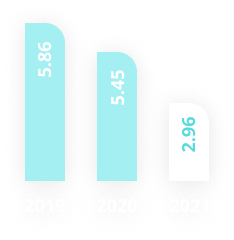

ACCIDENT

FREQUENCY RATE

(#/M Worked hours)

(#/M Worked hours)

reduction scope 1-2 carbon

emissions (vs 2020)

Key highlights

Climaflex® - taking on the diaper 'A-brands' in Europe

Climaflex is a next-generation baby diaper core technology. It makes Ontex the first retail manufacturer to offer diaper absorption even with heavy baby movement and baby comfort on par with leading A-brand advertisements in key markets in Europe. The technology has been launched under Ontex's 'Little Big Change' brand in six European countries (Austria, Belgium, France, Germany, Luxembourg, The Netherlands). It will be

rolled out across other retailer diaper brands

in 2022.

Ontex has several granted and pending patents protecting the inventions that make up Climaflex, covering Europe, the US and Mexico.

Ontex has several granted and pending patents protecting the inventions that make up Climaflex, covering Europe, the US and Mexico.

Key highlights

Breaking new ground on CO2 targets

Ontex broke new ground in September 2021 on a large solar installation at its factory in Ortona, Italy. The installation – the largest in Italy for on-site solar power generation and consumption - will produce 11.6 GWh of electricity per year, equivalent to the yearly consumption of more than 3,500 households.

All Ontex group factories in Europe run on 100% renewable electricity. And the company is continuing to develop more solar power installations at its European and North American plants.

"As demand for sustainably produced electricity is expected to increase, we prefer to have direct access to electricity that is produced onsite in a sustainable way," said Annick De Poorter, Ontex EVP for R&D and Sustainability. "We can now produce more than a quarter of the electricity we need to manufacture essential hygiene goods at our factory in Italy. This is another step towards our goal to have carbon- neutral operations by 2030."

All Ontex group factories in Europe run on 100% renewable electricity. And the company is continuing to develop more solar power installations at its European and North American plants.

"As demand for sustainably produced electricity is expected to increase, we prefer to have direct access to electricity that is produced onsite in a sustainable way," said Annick De Poorter, Ontex EVP for R&D and Sustainability. "We can now produce more than a quarter of the electricity we need to manufacture essential hygiene goods at our factory in Italy. This is another step towards our goal to have carbon- neutral operations by 2030."

Key highlights

Ontex helping to make diaper recycling a reality

Ontex has partnered with Belgian start-up Woosh on an ambitious diaper recycling service. Woosh launched its delivery and collection service of Ontex’s Little Big Change diapers for nurseries last April in the Belgian city of Mechelen. By 2023, it aims to reach 1,000 nurseries in Belgium and expand its service to other European countries. For Ontex, the partnership is another step in its commitment towards finding alternatives to landfill and incineration for disposable used diapers.

"In a nursery, diaper waste is a daily challenge," said Fatima Arbaji of Het Zandkasteel nursery in Mechelen. "Approaching diaper,waste in an ecological way is certainly not straightforward. We tested the Little Big Change diapers and are happy with the result. It’s a good feeling to help address the environmental challenge related to diaper waste."

"In a nursery, diaper waste is a daily challenge," said Fatima Arbaji of Het Zandkasteel nursery in Mechelen. "Approaching diaper,waste in an ecological way is certainly not straightforward. We tested the Little Big Change diapers and are happy with the result. It’s a good feeling to help address the environmental challenge related to diaper waste."

Key highlights

Coming full circle with compostable diapers

Ontex has joined forces with Les Alchemistes, a French circular economy company which is aiming to compost 500 million diapers by 2030.

"Our goal is to make the separate collection and composting of used, compostable diapers a reality", said Maïwenn Mollet, director of the Fertile Diapers program at Les Alchimistes. "We are very happy that Ontex and their brand Little Big Change are joining our mission. Ontex has the engineering knowledge and resources to design diapers that can be compostable." Ontex and Les Alchimistes have set up a pilot project at Les Alchimistes’ industrial composting site near Paris with the aim of proving that composting of Ontex diaper pads is possible. The Ontex Little Big Change brand has developed a new diaper system. This consists of a reusable outer diaper made of cotton and a disposable diaper pad designed to be industrially compostable.

"Our goal is to make the separate collection and composting of used, compostable diapers a reality", said Maïwenn Mollet, director of the Fertile Diapers program at Les Alchimistes. "We are very happy that Ontex and their brand Little Big Change are joining our mission. Ontex has the engineering knowledge and resources to design diapers that can be compostable." Ontex and Les Alchimistes have set up a pilot project at Les Alchimistes’ industrial composting site near Paris with the aim of proving that composting of Ontex diaper pads is possible. The Ontex Little Big Change brand has developed a new diaper system. This consists of a reusable outer diaper made of cotton and a disposable diaper pad designed to be industrially compostable.

Key highlights

Ontex ramps up North American operations

Ontex's new manufacturing facility in Stokesdale, North Carolina is scheduled to begin production in Q1 2022. The North Carolina location was selected because approximately half the U.S. population lives within a 1,000 km/650-mile radius. This development gives Ontex coast-to-coast sourcing flexibility in the North American market.

In an earlier move to build capacity in North America, Ontex acquired the assets of Albaad Massout Yitshak Ltd, another personal hygiene products company operating in Rockingham County. The 2020 deal included the acquisition of diaper production lines and feminine production line assets.

In an earlier move to build capacity in North America, Ontex acquired the assets of Albaad Massout Yitshak Ltd, another personal hygiene products company operating in Rockingham County. The 2020 deal included the acquisition of diaper production lines and feminine production line assets.

Key highlights

New beginnings in Germany

The Ontex manufacturing plant in Mayen, Germany will cease production in mid-2022, but the location will continue to play a pivotal role in the Ontex story.

As production winds down, work will continue on making the Mayen plant a new Ontex Center of Excellence for Global Process Engineering and Global Platform Innovation.

"Choices needed to be made, and as Mayen's production capacity was not fully utilized, we have decided that Mayen's role in the group will be to focus on Global Process Engineering and Global Platform Innovation for the Ontex Group. It will be one of the driving locations to bring innovation even faster to the market", said Markus van Gumpel, VP Manufacturing Europe.

As production winds down, work will continue on making the Mayen plant a new Ontex Center of Excellence for Global Process Engineering and Global Platform Innovation.

"Choices needed to be made, and as Mayen's production capacity was not fully utilized, we have decided that Mayen's role in the group will be to focus on Global Process Engineering and Global Platform Innovation for the Ontex Group. It will be one of the driving locations to bring innovation even faster to the market", said Markus van Gumpel, VP Manufacturing Europe.

Key highlights

Ontex reaches out to families in need

Ontex Santé France donated more than 469,000 baby diapers last December to families in need around its factory in Dourges,

northern France.

"For families who live in poverty, the purchase of baby diapers disproportionally impacts their family budget, especially for single parents or large families. People that were already financially struggling before the pandemic started struggle even more today", said Fabienne Berquier, of the Red Cross which distributed the Ontex diapers. "This important donation by Ontex helps us to fulfil an urgent need during the coldest and one of the most expensive months of the year for many local families."

Between the start of the pandemic until the end of 2021, Ontex donated more than 5.1 million product items in 14 countries on four continents. "For many years, and as part of our sustainability strategy, we have been donating locally and try to reach the most vulnerable groups in society, such as the elderly in poverty, families with financial difficulties and refugees," said Stéphanie Durot, general manager for Ontex in France and the Benelux countries.

"For families who live in poverty, the purchase of baby diapers disproportionally impacts their family budget, especially for single parents or large families. People that were already financially struggling before the pandemic started struggle even more today", said Fabienne Berquier, of the Red Cross which distributed the Ontex diapers. "This important donation by Ontex helps us to fulfil an urgent need during the coldest and one of the most expensive months of the year for many local families."

Between the start of the pandemic until the end of 2021, Ontex donated more than 5.1 million product items in 14 countries on four continents. "For many years, and as part of our sustainability strategy, we have been donating locally and try to reach the most vulnerable groups in society, such as the elderly in poverty, families with financial difficulties and refugees," said Stéphanie Durot, general manager for Ontex in France and the Benelux countries.

Key highlights

Creating a learning culture - online

In 2021, Ontex office-based employees around the world dived into the digital learning adventure. They were given access to LinkedIn Learning, a digital library of more than 16,000 training courses across eight languages. The platform has both micro and in-depth learning modules and is accessible via mobile devices.

The online modules give employees the option of developing their skills when it suits them best. The content is personalized to the individual learner to provide professionally produced and tailor-made learning paths curated by Ontex experts.

Courses are regularly updated and new ones added every month. The response has been outstanding: with 2,069 users following more than 9,200 hours of training in 2021. Ontex people are eager to learn! So much so that Ontex was nominated to the LinkedIn Learning Talent Awards, where we featured in the top three for "Creating a Learning Culture".

The online modules give employees the option of developing their skills when it suits them best. The content is personalized to the individual learner to provide professionally produced and tailor-made learning paths curated by Ontex experts.

Courses are regularly updated and new ones added every month. The response has been outstanding: with 2,069 users following more than 9,200 hours of training in 2021. Ontex people are eager to learn! So much so that Ontex was nominated to the LinkedIn Learning Talent Awards, where we featured in the top three for "Creating a Learning Culture".

Key highlights

Single supply chain organization

Our industrial transformation agenda is about unlocking significant value from our end-to-end supply chain, building on our network and scale to take performance to the next level. We have high fixed cost and a very high dependency to commodity and inflation through the 60% portion of raw materials and indirectly on other operating costs.

Headline actions here include streamlining our diverse asset base using faster equipment on harmonized platforms. This will allow us to reduce the number of lines by 20%, and as a consequence improve capacity utilization by 10 points over time.

Furthermore, we now have end-to-end accountability for bringing to the market a certain product features in a in an organized way. This is already enabling qualification in record time. Our most experienced staff are all saying that qualification has never been as good as now - fast, pragmatic and working.

Headline actions here include streamlining our diverse asset base using faster equipment on harmonized platforms. This will allow us to reduce the number of lines by 20%, and as a consequence improve capacity utilization by 10 points over time.

Furthermore, we now have end-to-end accountability for bringing to the market a certain product features in a in an organized way. This is already enabling qualification in record time. Our most experienced staff are all saying that qualification has never been as good as now - fast, pragmatic and working.

Key Highlights

Climaflex® - taking on the diaper 'A-brands' in Europe

Breaking new ground on CO2 targets

Ontex helping to make diaper recycling a reality

Coming full circle with compostable diapers

Ontex ramps up North American operations

New beginnings in Germany

Ontex reaches out to families in need

Creating a learning culture - online

Single supply chain organization

T2G

T2G integrated

Digital

E-commerce support